Introduction to the Structure of Gantry Crane

1.Structural characteristics

The gantry crane is a widely used heavy-duty lifting equipment, and its main structural characteristics include the following aspects:

1. It consists of a pair of tall gantry frames and a running mechanism spanning over two gantry frames, including the main beam, end beam, car, giant pulley, winch, large steel wire rope, etc.

2. The gantry is composed of two large herringbone shaped steel bars, with the middle part being a bridge type continuous beam. The ends of the two ends are combined into a whole using large mechanical connection equipment (such as columns).

3. The operating mechanism generally consists of an electric motor, reducer, brake, and electrical control system, and can travel along the straight track of the main beam.

2.Components

The gantry crane mainly consists of the following parts:

1. Portal crane: composed of two tower cranes, one above and one below, assembled from large steel components and steel plates.

2. Pulley: The steel wire rope supporting the crane can be controlled by a mechanism to change the position and angle of the pulley to adapt to various working conditions.

3. Main beam: The core component of a crane, composed of multiple welded steel components, usually with a box shaped section in the middle and connected by web plates.

4. Vehicle: It mainly consists of a driving axle, wheelset, driving mechanism, and suspension mechanism, and can run and move laterally on the main beam.

5. Winch: Used to roll and loosen the steel wire rope of the crane, and is also one of the core components of the crane.

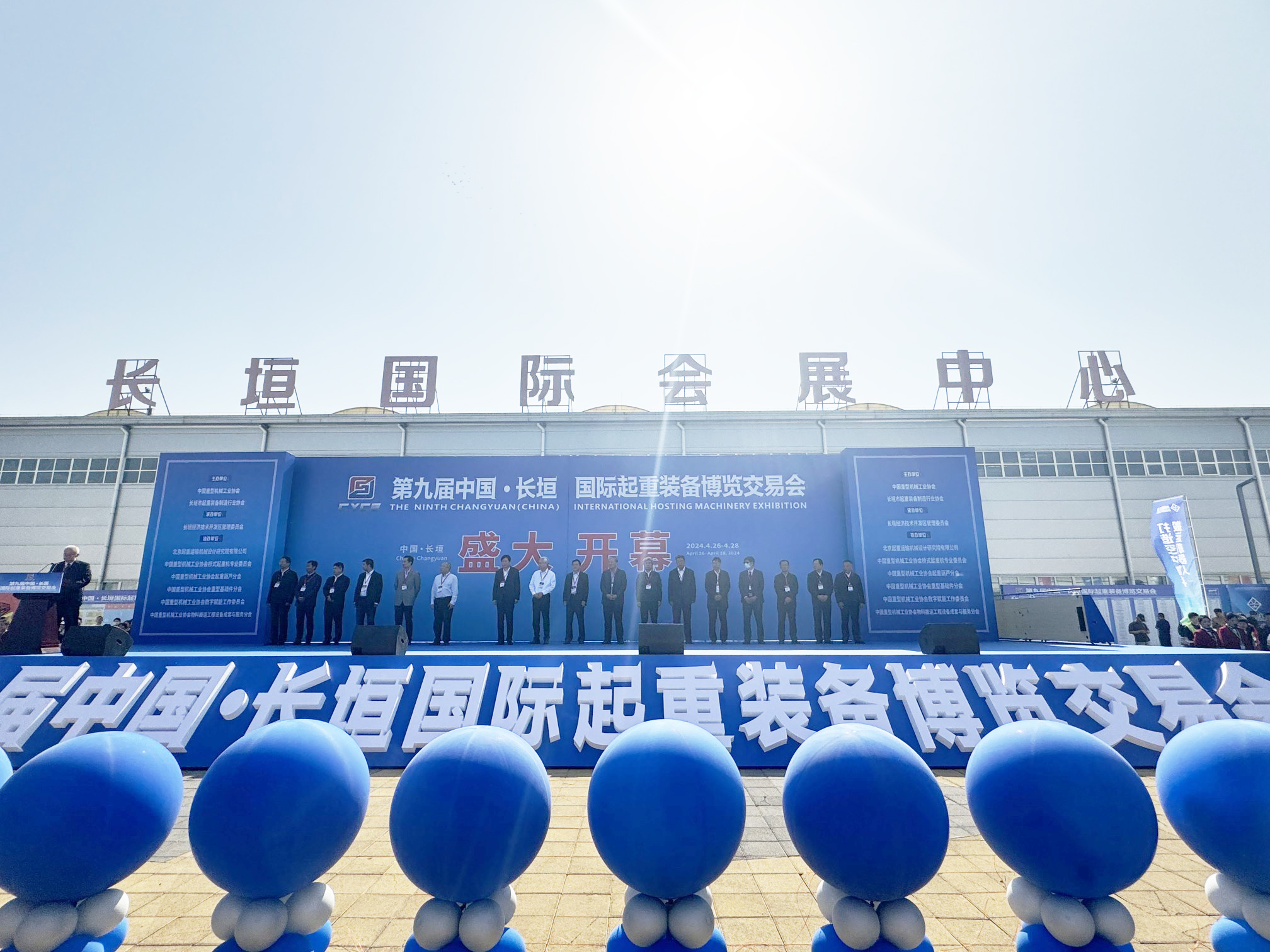

3. Application areas and advantages

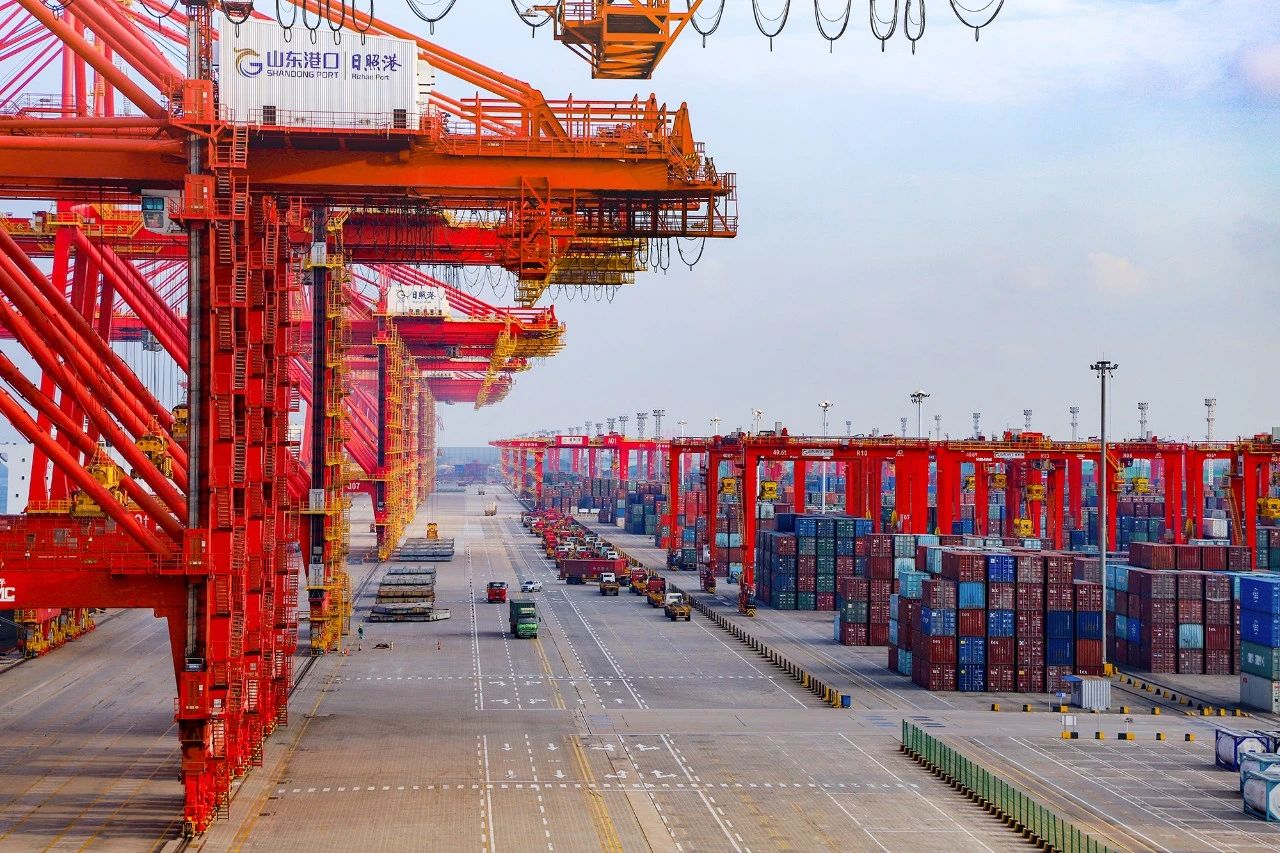

Bridge and gantry cranes are mainly used for loading, unloading, and transportation of goods in factories, docks, freight yards, construction sites, and other places. It has the characteristics of heavy lifting capacity, large span, high height, and large amplitude, and can meet various lifting needs.

Compared with traditional lifting equipment, gantry cranes have obvious advantages, including the following aspects:

1. It has a wide range of adaptability and can be used in different places such as factories, docks, and freight yards.

2. Strong load-bearing capacity, with a lifting capacity of several hundred tons or more.

3. High work efficiency, capable of achieving efficient loading and unloading operations.

4. The operation is simple and easy to master, which can improve work efficiency while ensuring safety.

5. Maintenance is simple and cost-effective, usually only requiring regular inspection and replacement of lubricating oil, cleaning of cranes, and other operations.

4. Working principle and maintenance methods

The working principle of a gantry crane is to use an electric motor to drive the wheels, and to connect objects through steel wire ropes for lifting and movement. In order to ensure the safety and stability of the crane, it is necessary to carry out maintenance work on the crane regularly. The specific details are as follows:

1. Regularly inspect all components of the crane for cracks or damage.

2. Clean the surface, pulleys, and various components of the crane.

3. Regularly replace the lubricating oil of the crane to ensure the lubrication effect of the machine.

4. Check whether the wiring of electrical equipment is normal and whether each controller is sensitive.

5. Regularly inspect and test the crane to ensure its performance and safety.

[ Conclusion ]

The gantry crane is a widely used heavy-duty lifting equipment, with unique structural characteristics and components, as well as a wide range of application fields and advantages. When using a crane, it is necessary to operate and maintain it correctly according to regulations to ensure the safety and stability of the crane.